Introduction to LVDT: Linear Variable Differential Transformer

Inductive Sensors

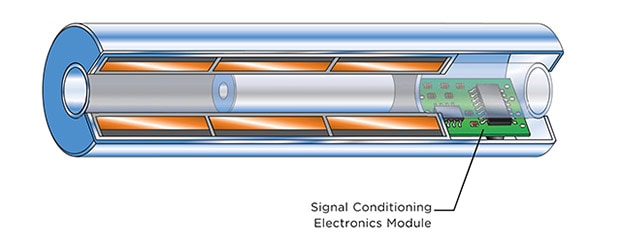

Linear Variable Differential Transformer (LVDT) is a type of inductive sensor used to calculate position or speed. These sensors operate based on the principle of alternating electrical currents. By utilizing the current induced by a magnetic field, inductive sensors can effectively detect nearby metal objects.

Introduction to the concept of LVDT and inductive sensors

LVDT is a widely used inductive sensor that provides accurate position measurements in various applications. The concept behind LVDT involves the use of transformer windings and a movable core to sense linear displacement accurately.

Exploring the working principle and application of LVDT

The working principle of LVDT is based on electromagnetic induction, where changes in position alter the mutual inductance between the primary and secondary windings, resulting in an output voltage proportional to the displacement. LVDTs are commonly used in industries such as aerospace, automotive, and manufacturing for precise measurement and control purposes.

LVDT: Theory and Operation

Understanding the theory behind Linear Variable Differential Transformer

Linear Variable Differential Transformer (LVDT) is an inductive sensor that operates by utilizing alternating electrical currents to detect position or speed changes. The core principle involves electromagnetic induction, where the induced current from a magnetic field aids in sensing nearby metal objects accurately.

Exploring the operation mechanism of LVDT in detail

The operation of LVDT revolves around the concept of transformer windings and a movable core that facilitate precise linear displacement measurements. By adjusting the position, the mutual inductance between primary and secondary windings varies, leading to an output voltage directly proportional to the displacement. LVDTs find widespread applications across industries demanding high precision and control.

Advantages of LVDT

Benefits of using LVDT in various industries

– LVDTs offer high accuracy and repeatability in measuring linear displacement, making them ideal for applications requiring precise control.- These sensors have excellent resolution and linearity, providing reliable data for position sensing in industries like aerospace, automotive, and manufacturing.- LVDTs are robust and durable, ensuring long-term performance even in harsh environments such as extreme temperatures or vibrations.

Analyzing the advantages of LVDT over other sensor types

– LVDTs have a wide measurement range compared to other sensors, allowing for versatile applications across different industries.- Their non-contact operation eliminates friction and wear issues, leading to extended sensor lifespan and minimal maintenance requirements.- The inherent immunity to electromagnetic interference makes LVDTs a preferred choice for critical measurement tasks requiring high accuracy and stability.

Applications of LVDT in Industry

Exploring the wide range of applications of LVDT in different industries

- LVDTs find extensive usage in industries like aerospace, automotive, and manufacturing for tasks requiring precise linear displacement measurements due to their high accuracy.

- These sensors are employed in monitoring position and speed in machinery, ensuring operational efficiency and precise control.

- LVDTs are utilized in automated systems for feedback control, quality assurance, and safety applications across various industrial sectors.

Case studies showcasing the practical use of LVDT sensors

- In the aerospace industry, LVDTs are essential for monitoring structural deflections in aircraft wings, ensuring safety and structural integrity.

- Automotive manufacturers use LVDTs in suspension systems to measure ride height accurately, improving vehicle performance.

- LVDTs play a crucial role in the manufacturing sector by enabling precise positioning in robotic assembly lines, enhancing production efficiency.

LVDT vs. Other Sensor Technologies

Comparing LVDT with other sensor technologies such as capacitive sensors

- LVDTs excel in industries like aerospace, automotive, and manufacturing due to their precise linear displacement measurements, unlike capacitive sensors.

- In machinery, LVDTs ensure operational efficiency and precise control, a feature not always provided by other sensor technologies.

- Across industries, LVDTs stand out in automated systems for feedback control, quality assurance, and safety applications compared to capacitive sensors.