Introduction

Definition of Drives and Electrical Drives

– A drive is an electrical or electronic device utilized for regulating the speed and movement of electrical machines such as motors and robots. – Electrical drives are controllers for motor speed, available in constant and variable speed forms. – They are widely deployed in various industries due to their adaptability and efficiency.

Importance of Drive Controllers

– Drive controllers play a crucial role in ensuring optimal performance and functionality of motors and machines. – They enable precise speed control, enhancing productivity and efficiency in industrial processes. – Additionally, drive controllers contribute to energy savings and operational cost reductions through their sophisticated control mechanisms.

Basics of AC Drives

Functionality and Components of AC Drives

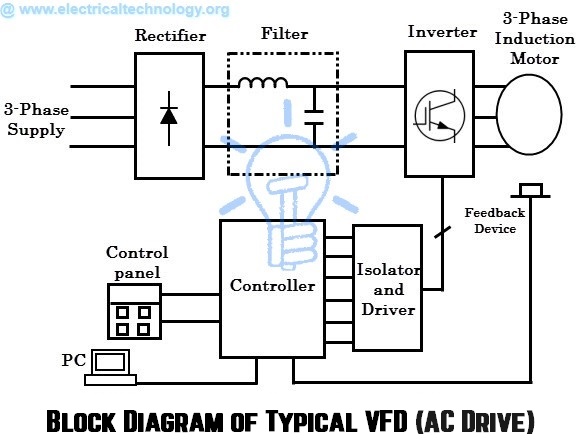

– AC drives are essential for regulating the speed of AC motors, enhancing operational control.- They consist of key components such as the rectifier, DC bus, inverter, and control unit.- The rectifier converts AC power to DC, the DC bus stores energy, the inverter changes DC back to AC, and the control unit manages operations efficiently.

Applications of AC Drives

– AC drives find extensive use in industries like manufacturing, HVAC systems, and conveyors.- They are crucial for variable speed operations, improving process efficiency.- Applications range from pumps and fans to complex machinery, showcasing the versatility and reliability of AC drives.

Basics of AC Drives

Functionality and Components of AC Drives

– AC drives play a vital role in regulating the speed of AC motors for optimal control.- Key components like the rectifier, DC bus, inverter, and control unit work together in AC drives.- The rectifier converts AC to DC, the DC bus stores energy, the inverter changes DC back to AC, and the control unit ensures efficient operations.

Applications of AC Drives

– AC drives are extensively used across industries such as manufacturing, HVAC systems, and conveyors.- These drives are essential for variable speed operations, enhancing overall process efficiency.- From simple pumps and fans to complex machinery, AC drives showcase versatility and reliability.

Basics of DC Drives

Functionality and Components of DC Drives

Applications of DC Drives

Main Differences between AC and DC Drives

Functionality and Components of AC Drives

– AC drives serve a crucial role in regulating the speed of AC motors for optimal performance by controlling key components including the rectifier, DC bus, inverter, and control unit.- The rectifier converts AC power to DC, the DC bus stores energy, the inverter transforms DC back to AC, and the control unit ensures smooth operations.

Applications of AC Drives

– AC drives find widespread use in various industries like manufacturing, HVAC systems, and conveyors for enhancing process efficiency through variable speed operations.- Ranging from simple pumps and fans to intricate machinery, AC drives demonstrate versatility and reliability.

Basics of DC Drives

Functionality and Components of DC Drives

Applications of DC Drives

Main Differences between AC and DC Drives

Functionality and Components of AC Drives

– AC drives play a crucial role in regulating the speed of AC motors by controlling key components such as the rectifier, DC bus, inverter, and control unit. The rectifier converts AC power to DC, the DC bus stores energy, the inverter transforms DC back to AC, and the control unit ensures smooth operations.

Applications of AC Drives

– AC drives are widely used in industries like manufacturing, HVAC systems, and conveyors to enhance process efficiency through variable speed operations. They demonstrate versatility and reliability in applications ranging from simple pumps and fans to complex machinery.

Basics of DC Drives

Functionality and Components of DC Drives

– DC drives are essential for controlling the speed of DC motors, utilizing components such as the rectifier, chopper, and control unit to adjust motor performance effectively.

Applications of DC Drives

– DC drives are commonly employed in various industrial settings to regulate the speed and performance of DC motors across different applications. They offer precise control and performance optimization in tasks requiring consistent speed adjustments.

Advantages of AC Drives

Cost-effectiveness and Maintenance Requirements

– AC drives are known for their cost-effectiveness and low maintenance requirements, making them a popular choice for applications involving AC motors.

Availability and Accessibility of AC Motors

– AC motors are readily available and less expensive, adding to the appeal of AC drives for a wide range of industrial and commercial applications.