Abnormal Operating Conditions for Induction Motors

Overheating Issues

In instances where induction motors operate under prolonged high loads or in environments with poor ventilation, **overheating** could occur. This can lead to insulation damage, motor winding failures, and ultimately motor breakdown.

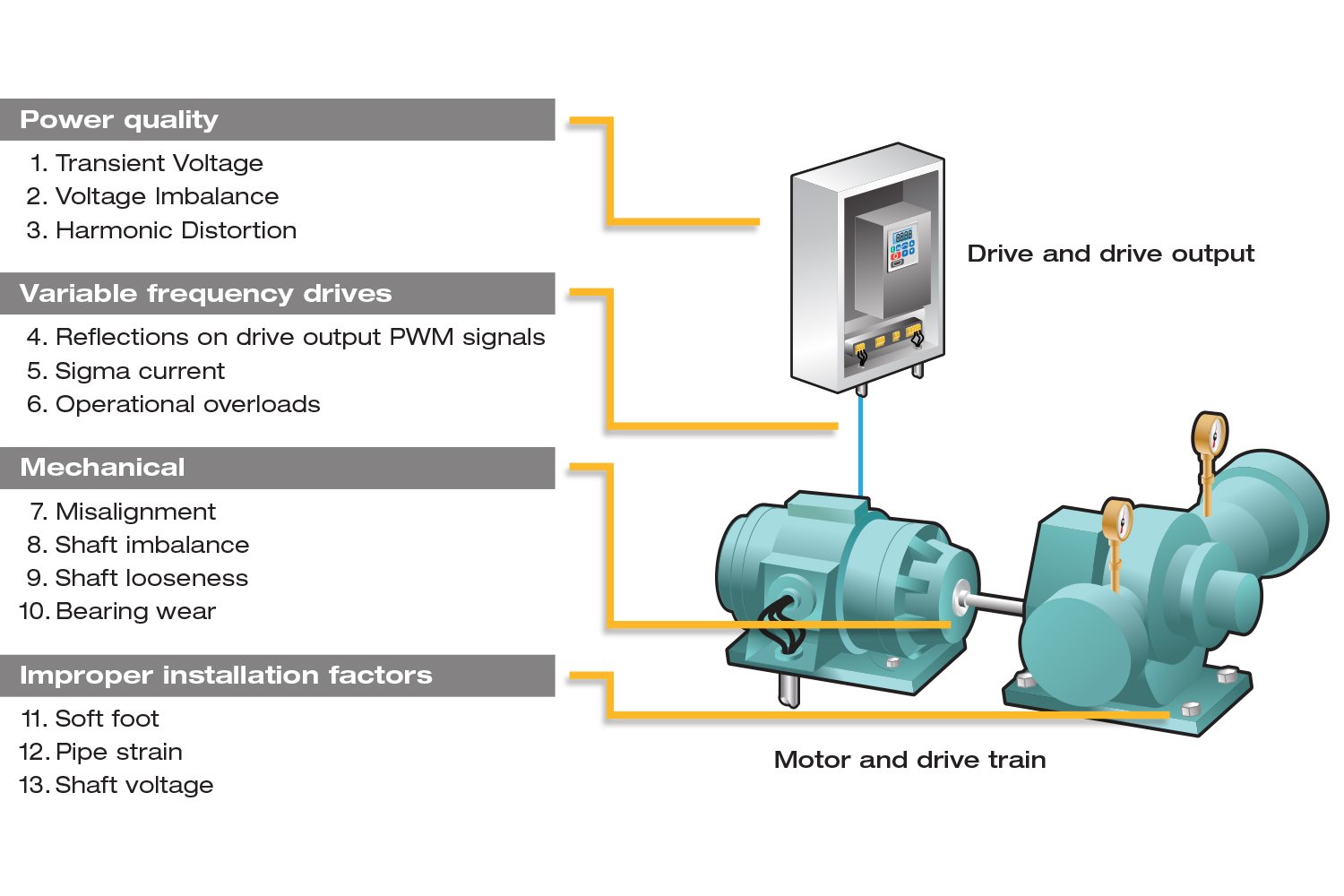

Voltage Fluctuations and Unbalance

**Voltage fluctuations** or unbalance in the supply can trigger abnormal operation of induction motors. Such conditions may impact the motor's efficiency, torque generation, and overall performance. It is crucial to ensure a stable and balanced power supply to prevent these issues.

Causes of Abnormal Operating Conditions

High Ambient Temperatures

**High ambient temperatures** are a common factor that can lead to abnormal operation in induction motors. When exposed to excessive heat, the motor may struggle to dissipate heat effectively, resulting in overheating issues and potential damage to internal components.

Insufficient Ventilation

**Insufficient ventilation** around the motor can also contribute to abnormal operating conditions. Inadequate airflow can prevent proper cooling, leading to increased temperatures within the motor casing. This lack of ventilation can accelerate wear and tear on the motor, reducing its efficiency and lifespan.

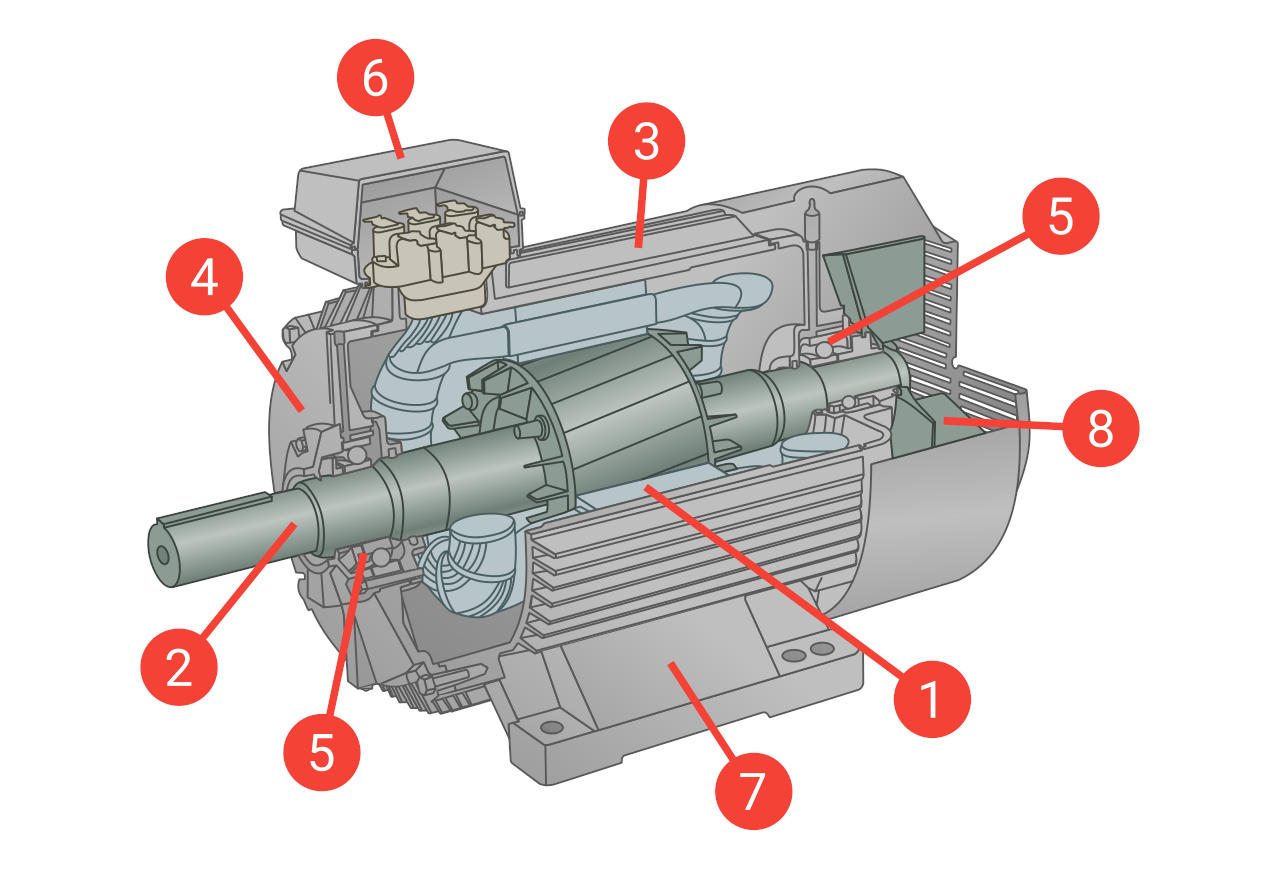

Bearing Failures

Lubrication Issues

**Lubrication issues** are a common reason behind bearing failures in machinery. When bearings are not adequately lubricated, increased friction can occur, leading to overheating and premature wear. This can result in operational malfunctions and potential damage to the equipment.

Misalignment Problems

**Misalignment problems** in machinery can put excessive stress on bearings, causing them to fail prematurely. When components are not properly aligned, it can lead to uneven distribution of forces and increased friction on the bearings. This can result in operational issues and reduced lifespan of the equipment.

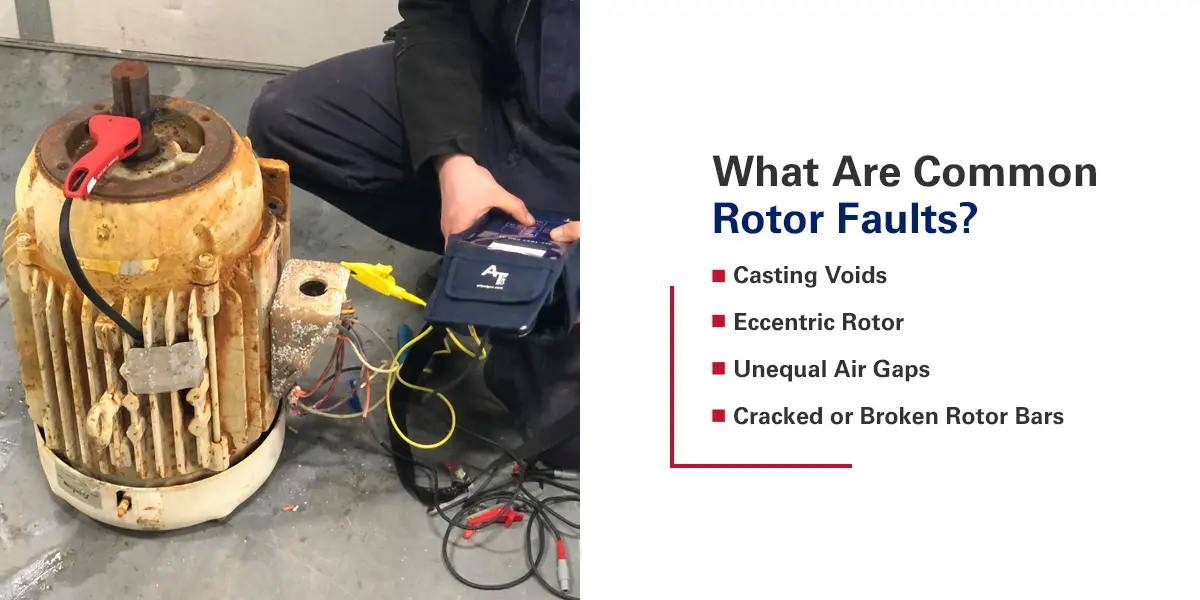

Rotor Faults

Broken Rotor Bars

**Broken rotor bars** can lead to imbalances in the current flow within the motor, causing fluctuations and potential overheating. This can result in reduced motor performance and eventual failure if not addressed promptly.

Uneven Air Gap

An **uneven air gap** in the motor can cause rotor misalignment, leading to increased friction and potential contact with the stator. This can result in operational issues and accelerated wear on the motor components. Regular maintenance and inspection are essential to prevent such rotor faults in three-phase motors.

Stator Winding Faults

Short Circuits

**Short circuits** in the stator winding can lead to excessive current flow, overheating, and potential damage to the motor. Identifying and rectifying short circuits promptly is crucial to prevent further complications and ensure the motor's safe operation.

Insulation Degradation

**Insulation degradation** in the stator winding can compromise the motor's efficiency and safety. It can result in electrical faults, increased risk of short circuits, and overall performance issues. Regular monitoring of insulation integrity is essential for the longevity and reliability of the three-phase motor.