Introduction to XLPE Insulated Medium & High Voltage Cables

Advantages of XLPE over other insulation materials

**XLPE** (Cross-linked polyethylene) stands out as the most commonly utilized insulation material in medium and high voltage cables due to its noteworthy benefits when compared to **PVC** (Polyvinylchloride) and other insulating materials. Its higher thermal and chemical resistance, better mechanical strength, and increased longevity make it a preferred choice in the industry.

Importance of medium and high voltage cables in electrical systems

The significance of medium and high voltage cables in electrical systems cannot be understated. These cables serve as vital conduits for transmitting power across various infrastructures, ensuring the efficient and reliable distribution of electricity to support industrial, commercial, and residential needs. The use of reliable insulation materials like XLPE plays a crucial role in maintaining the integrity and safety of these critical components.

Treeing in XLPE Insulated Cables

Understanding electrical treeing in XLPE insulation

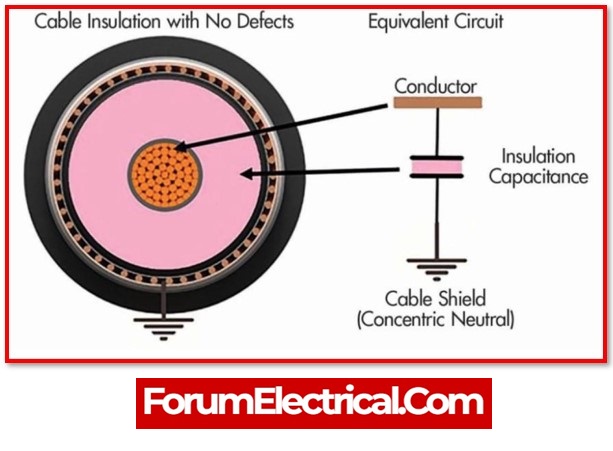

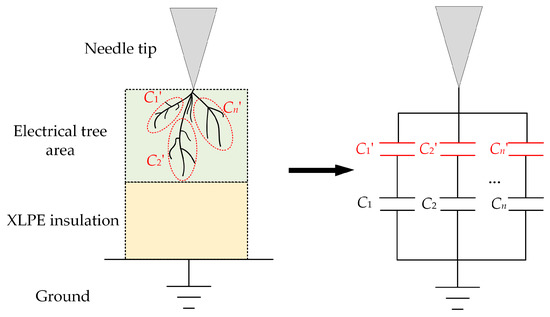

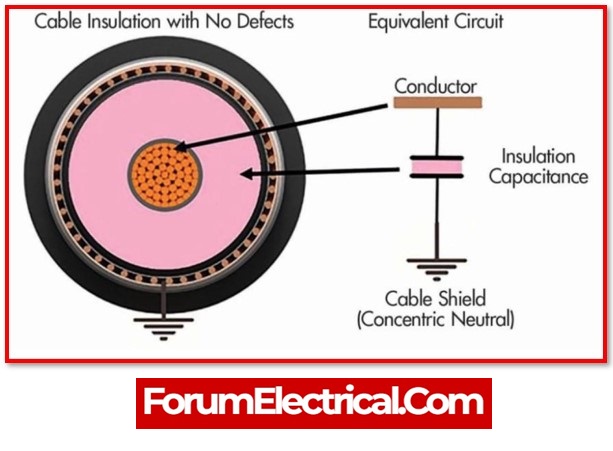

**Treeing** in **XLPE** insulation refers to the formation of tree-like partial discharge channels within the material, which can compromise its integrity over time. These microscopic channels can gradually propagate and weaken the insulation, potentially leading to breakdowns and failures in medium and high voltage cables.

Causes of treeing in medium and high voltage cables

Treeing can be caused by various factors, including **impurities** in the XLPE material, **mechanical stress**, **electrical overstress**, and **environmental conditions**. Understanding these **causes** is crucial in designing and maintaining reliable cable systems to prevent treeing-related issues.

Implications of Electrical Treeing

Impact of treeing on cable performance

**Treeing** in **XLPE** insulation can significantly impact the performance of medium and high voltage cables. The formation of partial discharge channels weakens the insulation, increasing the risk of breakdowns and failures. These **implications** highlight the importance of addressing treeing to ensure the reliability and longevity of cable systems.

Signs of treeing and potential risks

Identifying signs of **treeing**, such as **discoloration**, **surface cracks**, and **partial discharge**, is crucial in mitigating potential risks. Ignoring these indicators can lead to **catastrophic failures** and **downtime** in electrical systems. Therefore, proactive **inspection** and **maintenance** practices are essential in **detecting** and **remediating** treeing to prevent adverse consequences.

Prevention and Detection Methods

Strategies to prevent treeing in XLPE insulated cables

**Preventive measures** such as using **high-quality XLPE** materials, maintaining **proper cable installation**, and **avoiding excessive voltage stress** can help deter treeing in XLPE insulated cables. **Regular inspections** and **testing** also play a crucial role in identifying potential treeing issues early on.

Techniques for detecting and monitoring tree growth

**Diagnostic tools** like **partial discharge testing**, **thermal imaging**, and **acoustic detection** can aid in **detecting and monitoring** the growth of trees within XLPE insulation. **Periodic assessments** using these techniques enable early intervention to prevent further deterioration.

Case Studies and Examples

Real-life examples of treeing in medium and high voltage cables

In the past, there have been instances where treeing has been observed in XLPE insulated medium and high voltage cables due to factors like contamination, manufacturing defects, or improper installation. These cases highlight the importance of proactive maintenance and quality assurance in preventing treeing-related failures.

Lessons learned from past incidents

From past incidents, it is evident that early detection and mitigation of treeing can significantly extend the lifespan of XLPE insulated cables. Proper training of personnel, adherence to industry standards, and regular monitoring help in addressing potential treeing issues before they escalate into costly failures. Implementing a robust maintenance program based on the lessons learned from past incidents is essential in ensuring the reliability and safety of MV and HV cable systems.