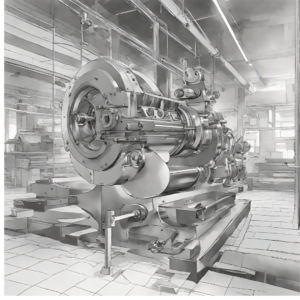

Tornos paralelos, or parallel lathes, are the unsung heroes of the machining world. With a legacy dating back to the Industrial Revolution, these machines have continually evolved to remain core to the manufacturing process. This post is a comprehensive guide to tornos paralelos, covering everything from their basic functionality to advanced usage, targeting machinists, manufacturing engineers, and hobbyists who seek a deeper understanding of these precision tools. Whether you’re a novice or an experienced craftsman, the information provided here will enrich your knowledge and enhance your appreciation of this essential equipment in various industries.

Understanding Tornos Paralelos

What is a Torno Paralelo?

The torno paralelo, or parallel lathe, is a type of lathe machine that rotates a piece of work on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation with tools applied to the workpiece to create an object which has symmetry about an axis of rotation. It is a crucial component of any machinist’s toolkit and is renowned for its precision in producing cylindrical parts.

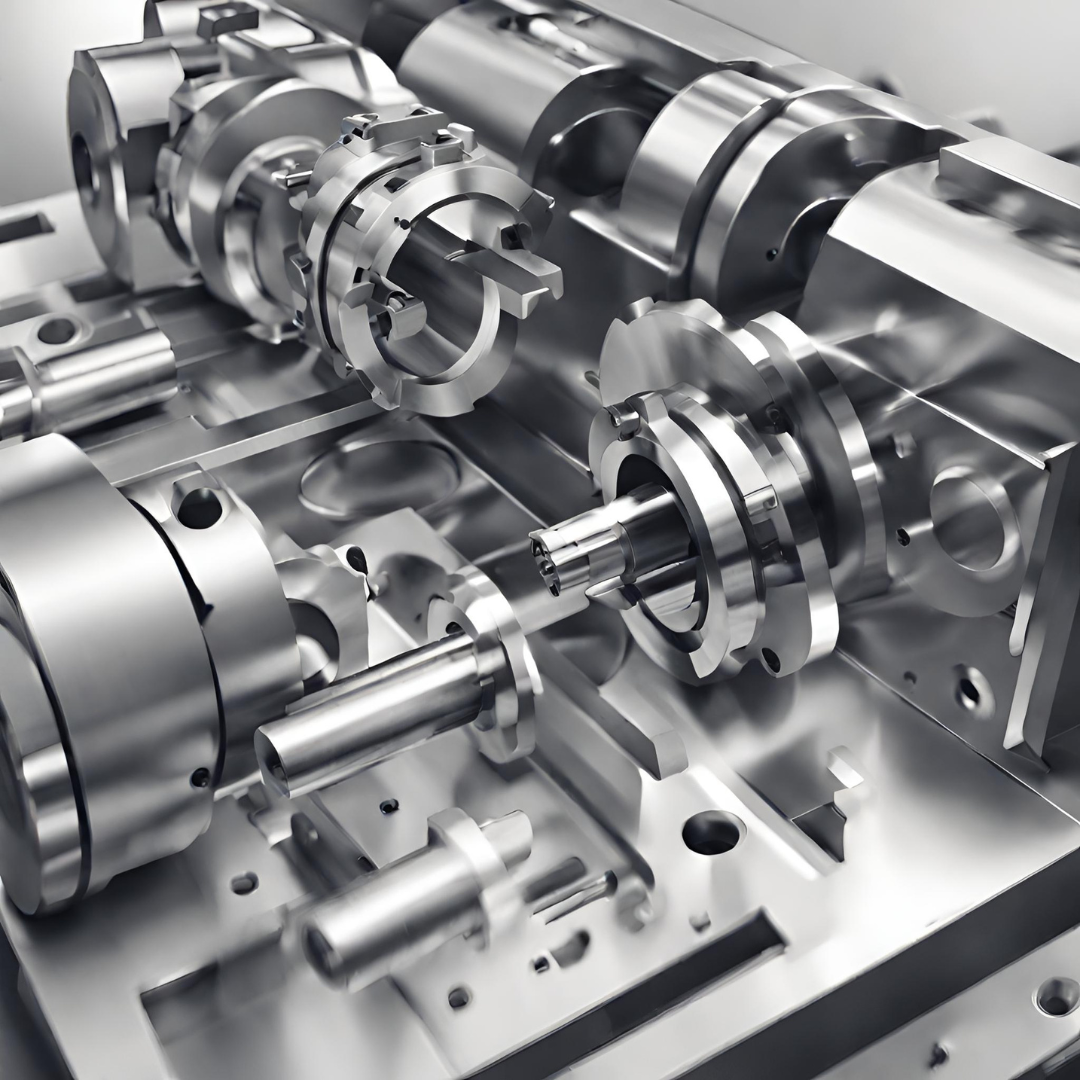

The Anatomy of a Torno Paralelo

A torno paralelo consists of several crucial components, each serving a specific function:

- Bed: The foundation of the torno, typically made of cast iron, that supports all the parts and provides a sturdy structure.

- Headstock: Positioned at the left end of the bed, it houses the main spindle, gear box, and other drive mechanisms.

- Tailstock: On the opposite end of the headstock, the tailstock can be repositioned along the bed and clamps the workpiece to prevent movement.

- Carriage: The moving assembly which traverses along the bed, carrying the cutting tools.

- Cross-slide: Part of the carriage that provides a cutting tool with a means of motion perpendicular to the workpiece rotation.

- Lead Screw: A threaded rod that engages the carriage to automate the longitudinal feed of the tool during rotation.

Applications of Tornos Paralelos

Tornos paralelos find applications in a myriad of industries due to their ability to work with a variety of materials, including metals, wood, and plastics. Some common applications include:

- Precision Metalwork: Tornos paralelos excel in producing high-precision metal components, such as shafts, pulleys, and gear blanks.

- Prototyping: For creating initial prototypes and small batches of products for testing and evaluation.

- Educational Purposes: Machining and engineering students often use parallel lathes to learn the basics of metalworking and turning.

Tornos Paralelos vs. Other Lathes

How Do Tornos Paralelos Differ?

Compared to other lathe types, such as the turret lathe, engine lathe, or center lathe, the torno paralelo distinguishes itself in a few key ways:

- Design and Size: Torno paralelos are generally larger and more robust due to the heavy-duty work they are designed to handle.

- Versatility: While specialized lathes may excel at certain tasks, the torno paralelo is more versatile, making it suitable for a wider range of operations.

- Operational Control: These lathes often feature more manual control, which can be beneficial for precision work and skill-based operations.

The Unique Benefits of Tornos Paralelos

For many users, the torno paralelo is the optimal choice for its advantages, which include:

- Power and Stability: Their robust design and build provide durability, power, and stability when working on heavy or large components.

- Large Threading Capabilities: Tornos paralelos often have special gearboxes that enable them to cut a wider range of screw threads.

- Automatic Operation Options: Modern torno paralelos can be equipped with automation features for complex, repetitive tasks, without compromising on accuracy.

Choosing the Right Torno Paralelo

Factors to Consider

Selecting the right torno paralelo for your needs is crucial. Consider the following factors:

- Size and Capacity: The size of the machine should correlate with the maximum diameter and length of the workpieces you intend to work on.

- Speed and Power: The torque and RPM range of the lathe’s spindle will determine the variety of materials and operations you can perform.

- Precision and Tolerance: Look for lathes that offer features such as digital readouts, high-quality spindles, and sturdy tool posts for precise work.

Tailored Options for Different Users

- Machinists: Prioritize machines with extensive tooling options and attachments for maximum versatility.

- Engineers: Efficiency and accuracy should be the focus, with features like digital displays and automatic tool changers.

- Hobbyists: A balance of affordability and functionality is key, with an understanding that more complex features may not be necessary for all projects.

Maintenance and Best Practices

Ensuring Longevity and Optimal Performance

Proper maintenance is crucial in keeping your torno paralelo in top condition. Regular practices should include:

- Lubrication: Keep all the moving parts lubricated to ensure smooth operation and reduce wear.

- Alignment Checks: Regularly verify the alignment of the tooling to maintain precision in your machined parts.

- Cleaning: Routinely clean the machine to prevent the buildup of materials that could affect its performance.

Safe Operation

Operation of the torno paralelo should always be done with safety in mind:

- Training: Ensure all operators are adequately trained in lathe operation and safety procedures.

- Personal Protective Equipment: Always wear the recommended PPE, including safety glasses and gloves.

- Machine Guards: Keep all machine guards in place to prevent contact with moving parts during operation.

The Future of Tornos Paralelos

Advancements and Innovations

The field of machining is continually advancing, and torno paralelos are no exception. Expect to see:

- Integration with Digital Technology: More lathes will incorporate digital interfaces for easier programming, monitoring, and data analysis.

- 3D Printing Integration: Hybrid machines that combine traditional turning with 3D printing for even greater part design possibilities.

- Sustainability Focus: Newer models will likely incorporate more eco-friendly materials and practices.

Their Role in an Evolving Industry

Despite the rise of new technologies, the role of the torno paralelo remains essential. Its unmatched precision and ability to work with a wide range of materials ensure it will continue to be a fixture in manufacturing, both in large-scale industries and small workshops.

Conclusion

Tornos paralelos are the workhorses of machinists, the precision tools of engineers, and the invaluable assets of hobbyists. Their versatility, strength, and ability to deliver high-quality manufacturing make them indispensable. Whether you’re shaping the cogs of industry or the hobbyist crafting for passion, the torno paralelo stands as a beacon of reliable, timeless efficiency in the world of machining. If you’re considering investing in one or just expanding your knowledge, remember that understanding these machines is not only about mastering a tool, but appreciating an art form that has been integral to human progress for centuries.